Well it's been a long month since I last got anything really significant done on my project. Work has been super busy lately. At the end of the fiscal year, my squadron gets really busy trying to compete for construction project funding that gets released in the last few days of the FY. And the pace at work didn't really slow down after 30 September either. We have a big inspection coming up at the end of October so that's kept me really busy as well. And then on top of that, I've had my Master's degree classes I've been trying to keep up with. So overall, just haven't had time to put much work into the airplane.

OK, OK... enough with the excuses. I did work a little bit on the project a few weeks ago to correct my mistake on the forward spar reinforcing angle. That fix went pretty quickly, so I don't have any pictures of it. Anyway, I got back to really working on the project yesterday, completing some prep work on the left-side horizontal stabilizer by match drilling and match drilling the skin and skeleton. This all went pretty smoothly and got me really excited to see the skin clecoed to the skeleton... awesome!

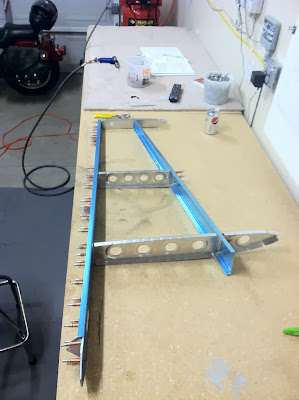

Today I was able to work through all of the drilling and match drilling on the right-side horizontal stabilizer. This work included some fluting of the ribs to ensure they were completely straight (something that took me some time to figure out). As with the left side, everything went pretty well. I had some struggles getting the skin to line up with the skeleton just right, but figured it out pretty quickly.

|

| Fluting the ribs to straighten them |

|

| Left-side HS skeleton clecoed together |

|

| Using a lot of clamps to hold things in place |

|

| A close up of a little blood. Now I can say I've bled and sweated for this project... no tears yet. Those skins are sharp though! |

|

| Left-side HS all drilled and match drilled |

|

| Right-side HS drilled and match-drilled |

|

| Proof that I am actually doing this work. ha! |

It felt really good to get back to work on the project... and to make some significant progress to boot! I've disassembled everything at this point and I will now deburr all of the edges and holes, dimple the skins and understructure, and then prep the parts for primer. It'll likely be at least a week or so before I actually get to the primer, but I'm going to try to keep plugging away. We have the inspection I mentioned coming up soon and I'll be working some really long hours on those days, so hopefully I can get the parts primed before that begins.

On a side note, after almost nine months of not flying, I got back up in the air last week. My medical expired while I was deployed, so I got that taken care of and then joined the base's aero club. After a Biennial Flight Review, I was cleared to fly again! Got a chance to have some fun flying around the local area with my buddy Scott this past weekend. It felt great to be back up there!

|

| Scott and me buzzing around the local area |