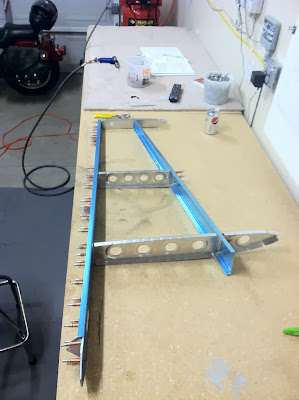

I spent last night dimpling the rest of the HS, including the understructure. The left side skin was dimpled using the DRDT-2 dimpler.

|

| The left skin all dimpled |

The understructure was dimpled using my pneumatic squeezer. This tool is awesome... it's essentially an air-actuated piston that squeezes either rivets or, when a dimple die is inserted in the tool, creates dimples. It makes quick work of making dimples... and as I found out, sometimes too quickly. Unfortunately, the squeezer got away from me a little bit and I ended up missing one of the holes while dimpling. Damn.

|

| The hole that was missed with the squeezer |

|

| A rivet placed in the hole so you can see how far off the accidental dimple was |

|

| A shot of the underside, showing the damage |

I've read on the Van's Air Force forums that this is a fairly common mistake that builders make, but most make it while dimpling skins. In almost every case, the builders were told that it wasn't a critical mistake and the builder could build on with a pretty simple fix. My mistake was made in the forward spar top flange though, so I didn't find any solutions to my particular mistake. So I contacted Van's builder support to see if they had a suggestion for me. I got an answer back pretty quickly... and as I figured, this hole is considered a critical joint because it is where a rib will attach, meaning it will see more stress than a hole where just the skin attaches. Because of the uncertainty of how much strength in that joint would be lost because of this mistake, the engineers recommended I replace the part. Such is my luck! So I've ordered the replacement part (luckily it was only $20) and will rework it when I receive it in the next few days.

This mistake was particularly frustrating because of the significant progress I've been making lately. I was hoping it'd be a quick fix, which would allow me to stick to my plan for this weekend. My plan was to prime all of the parts, which would've allowed me to get to pounding some rivets in the next week, but that will all have to wait. I'll chalk this up as a learning experience and make sure I'm taking my time to carefully dimple my parts with the pneumatic squeezer from now on.

So this weekend, I now plan to begin working on the vertical stabilizer, drilling and match drilling those parts. That way I won't be letting this mistake completely stop my progress. If I make some good progress on the VS, I may put myself in a situation that will allow me to prime both the HS and VS in one session. I'll keep you updated!

|

| All of the spars dimpled... one of which will be replaced |